About Us

Our chapter of Swedish clog history began over a hundred years ago in Troentorp, a small village just outside Båstad, in the south of Sweden.

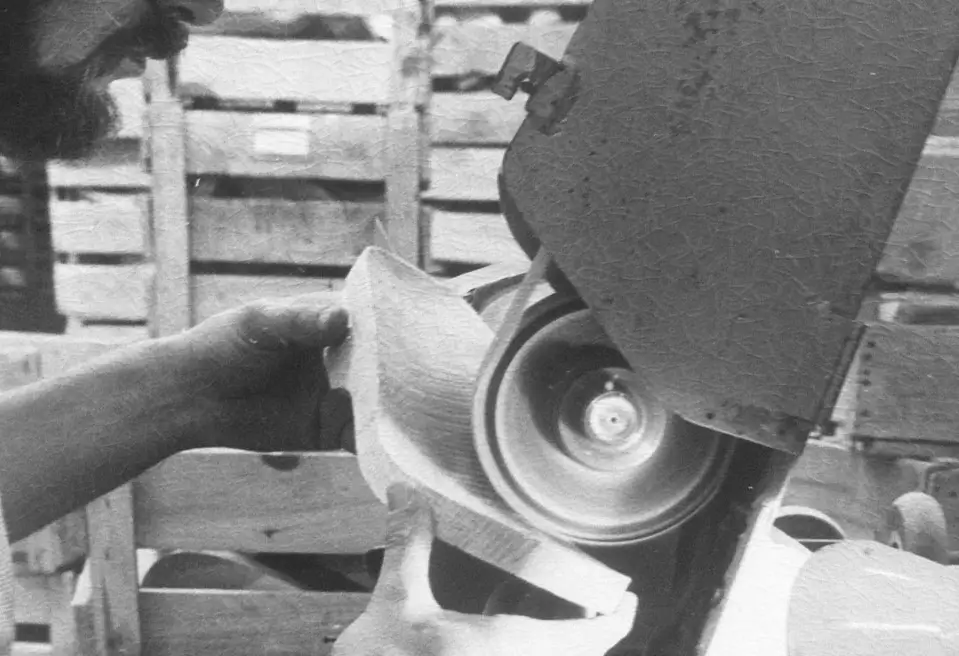

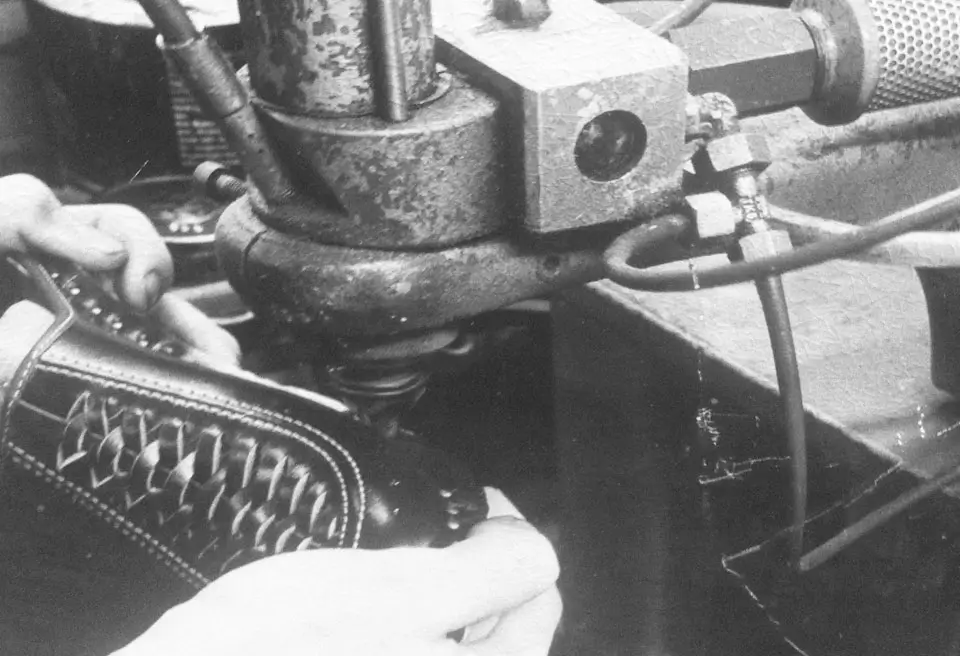

After spending eight years learning his craft from the local cobbler, in 1907 August Johansson was finally ready to start his own company, which he called Troentorp. Over the years, he developed and perfected the production process, and in 1942 August’s sons, Börje and Stig, took over the family business.

Today, we are proud to say that August Johansson’s legacy that started over 100 years ago is still alive in our factory. Though fully modernized to meet the needs of contemporary customers in terms of comfort and design, the knowledge and craftsmanship handed down through generations of cobblers are still visible in every pair of our wooden clogs.